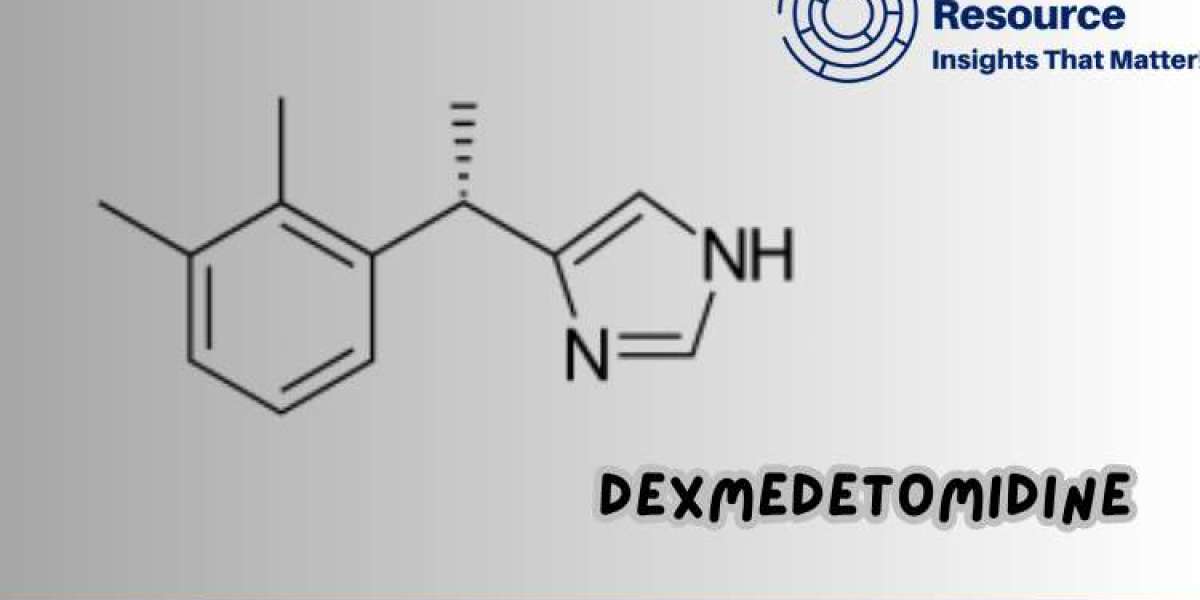

Dexmedetomidine is a highly specialized medication used primarily as a sedative in intensive care settings and during surgeries. Its unique properties, including its ability to provide sedation without respiratory depression, make it invaluable in critical care and anesthesiology. For pharmaceutical companies involved in the production or reliance on dexmedetomidine, understanding its production costs is essential for optimizing procurement, managing pricing strategies, and ensuring competitiveness in a regulated market. Procurement Resource offers comprehensive Dexmedetomidine Production Cost Reports that provide businesses with detailed insights, helping them make informed and cost-effective decisions.

Why Dexmedetomidine is Important

Dexmedetomidine is a sedative commonly used in ICU settings and for procedural sedation. Unlike other sedatives, it does not cause significant respiratory depression, making it ideal for critically ill patients. Its effectiveness in reducing agitation and providing stable sedation levels has made it a standard choice in critical care, particularly for patients needing prolonged sedation. Given its critical role in healthcare, understanding and optimizing the cost structure of dexmedetomidine production is essential for pharmaceutical companies seeking to offer affordable and accessible medications.

Request a Free Sample for Dexmedetomidine Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/dexmedetomidine/request-sample

Key Factors Influencing Dexmedetomidine Production Costs

The production of dexmedetomidine involves complex chemical synthesis, high standards of purity, and compliance with stringent regulatory guidelines. Below is a breakdown of the primary factors impacting dexmedetomidine production costs:

1. Raw Material Costs

Dexmedetomidine production relies on high-quality chemical compounds as starting materials, and each step in the synthesis requires precise reagents. The cost and availability of these raw materials are influenced by global market conditions, regulatory policies, and supply-demand dynamics in the pharmaceutical sector. Variability in the price of raw materials can lead to fluctuations in overall production costs, especially for a complex drug like dexmedetomidine, where purity and quality are essential.

For companies involved in dexmedetomidine production, securing stable, high-quality suppliers is crucial. Monitoring trends in raw material prices and anticipating supply chain disruptions can help manage costs effectively.

2. Synthesis and Processing Costs

Dexmedetomidine production involves intricate chemical synthesis steps that require specialized equipment, precise temperature controls, and highly skilled operators. Each stage, from initial synthesis to final crystallization, must adhere to rigorous standards to ensure the drug’s efficacy and safety. The synthesis process can be resource-intensive, requiring significant energy and controlled environments, further impacting production costs.

Implementing efficient synthesis techniques and investing in optimized processing technologies can help reduce production expenses while maintaining high standards of quality.

3. Labor and Operational Costs

The production of dexmedetomidine requires highly skilled personnel, including chemists and technicians, to manage the synthesis, quality control, and regulatory compliance processes. Labor costs vary depending on regional wage levels and labor availability, and maintaining compliance with Good Manufacturing Practices (GMP) requires ongoing investments in staff training and safety protocols.

Read the Full Report – https://www.procurementresource.com/production-cost-report-store/dexmedetomidine

Efficient labor management and adherence to operational standards are critical to controlling production costs. Investing in workforce training and implementing streamlined operational processes can enhance productivity and reduce expenses, ensuring consistent quality in dexmedetomidine production.

4. Quality Control and Testing Costs

Due to the high safety standards for pharmaceuticals, each batch of dexmedetomidine must undergo rigorous quality control testing to ensure purity, potency, and safety. These tests include chemical assays, stability testing, and microbiological assessments, all of which add to the overall production costs. Testing equipment, consumables, and quality assurance protocols are critical to ensuring that dexmedetomidine meets regulatory requirements and industry standards.

By optimizing quality control procedures and adopting advanced testing methods, companies can manage quality-related expenses more effectively, while maintaining high standards in dexmedetomidine production.

5. Regulatory and Compliance Costs

The pharmaceutical industry is highly regulated, and dexmedetomidine production is subject to stringent standards set by agencies like the FDA, EMA, and others. Compliance with these regulations involves detailed documentation, safety protocols, and periodic audits, all of which contribute to production costs. Regulatory compliance also requires investment in facility upgrades, waste management, and emissions control to meet environmental and safety standards.

Incorporating efficient compliance practices and staying current with regulatory updates can help manage compliance costs while ensuring that dexmedetomidine production aligns with global standards.

How Procurement Resource’s Dexmedetomidine Production Cost Reports Can Benefit Your Business

At Procurement Resource, we specialize in delivering Dexmedetomidine Production Cost Reports that simplify complex production costs into actionable insights. Our reports provide a detailed analysis of every cost factor involved in dexmedetomidine production, helping businesses understand their cost structure and identify areas for optimization.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/dexmedetomidine/ask-an-analyst

Key Features of Our Dexmedetomidine Production Cost Reports:

Detailed Cost Breakdown: Our reports cover raw materials, synthesis, labor, operational expenses, and compliance costs, offering a comprehensive view of dexmedetomidine production expenses. This transparency allows businesses to focus on areas with potential for cost savings and efficiency improvements.

Real-Time Data: The pharmaceutical market is dynamic, with prices and trends constantly changing. Our reports include up-to-date data and forecasts, enabling businesses to make strategic decisions based on current market conditions.

Price Trends and Analysis: We track pricing trends within the pharmaceutical industry, providing insights into anticipated changes in production costs. Understanding these trends helps companies develop effective procurement and production strategies to remain competitive.

Benchmarking and Comparison: Compare your production costs with industry benchmarks to identify areas for efficiency improvements and potential cost reductions. Benchmarking provides valuable insights into your company’s cost structure relative to industry standards.

Procurement Insights: Effective procurement strategies are essential in managing dexmedetomidine production costs. Our reports offer insights into supplier selection, contract negotiations, and raw material procurement to help businesses secure stable supplies and manage expenses effectively.

Request a Free Sample Report Today

To help you gain a better understanding of the value our reports provide, we invite you to request a free sample of our Dexmedetomidine Production Cost Report. This sample will give you a preview of the comprehensive data and analysis that Procurement Resource provides, empowering you to make informed decisions in dexmedetomidine procurement and production.

Why Partnering with Procurement Resource is a Strategic Choice

By partnering with Procurement Resource, your company gains access to valuable insights and expert analysis. Our Dexmedetomidine Production Cost Reports are designed to support decision-making with actionable data, helping you manage costs, optimize procurement, and improve supply chain efficiency. With our reports, you can stay ahead of market trends, mitigate risks, and maximize operational effectiveness.

We understand that each business has unique needs, and our reports are customizable to meet specific requirements. Whether your focus is on reducing costs, enhancing operational efficiency, or meeting regulatory standards, our team of skilled analysts provides the support and insights you need to succeed.

Request Your Free Sample – https://www.procurementresource.com/production-cost-report-store/dexmedetomidine/request-sample

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: [email protected]

Toll-Free Numbers:

USA copyright: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA